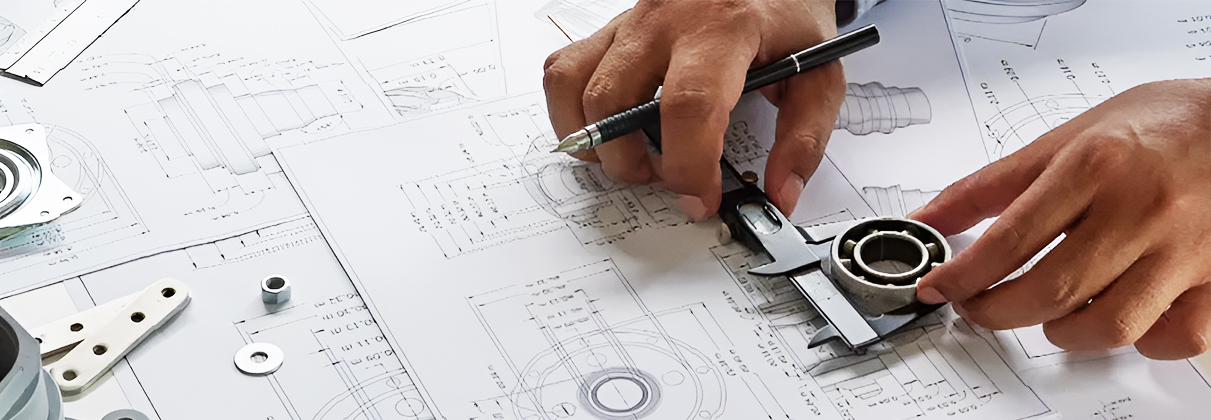

INSPECTION

Where Quality Meets Reliability

QUALITY CONTROL

Quality First: Ensuring Every Spare is Perfect

The Perfect Spares Inspection Department ensures all components undergo thorough checks before shipment. Each part is subjected to detailed visual inspections, precise measurements, and performance tests to meet industry standards. Our expert team meticulously documents all findings to maintain traceability. We prioritize quality and reliability, ensuring that only parts that pass our stringent evaluations receive final approval for shipment. This commitment guarantees our customers receive high-quality spare parts, giving them confidence in their performance and longevity.

The Inspection Department at Perfect Spares is dedicated to guarantee quality and reliability of various components through comprehensive inspections, stringent compliance checks, and rigorous testing protocols. This department meticulously identifies defects, verifies standards, and generates detailed reports aimed at enhancing our production processes. By maintaining such high standards, we ensure that only the finest products reach our customers, thereby upholding safety and fostering customer satisfaction.

Do you have questions about our product and service portfolio or would you like personal advice?

Contact now